Our company uses the latest manufacturing technologies and qualitOur company uses the latest manufacturing technologies and quality control processes to provide our customers with products of the highest quality. We currently have two fully automated production lines, where from SMD components in size 0201 to integrated circuits in QFP and BGA/uBGA packages, we can undertake the implantation of all types of components.y control processes to provide our customers with products of the highest quality.

Automatic Production Lines

We currently have two fully automated production lines, using Panasonic and Samsung implanting machines and stencil printers. The ideal performance of our Heller and Rehm reflow ovens can be further tailored to the needs of each product with the KIC K2 thermal profiler. The technology of our manufacturing base is flexible, from SMD components in size 0201 to integrated circuits in QFP and BGA/uBGA packages, we can undertake the implantation of all types of components with excellent quality. Read more about the cooperation between Panasonic and Albacomp EA in the article Hungarian prototyping specialist Albacomp EA relies on Panasonic Factory Solutions

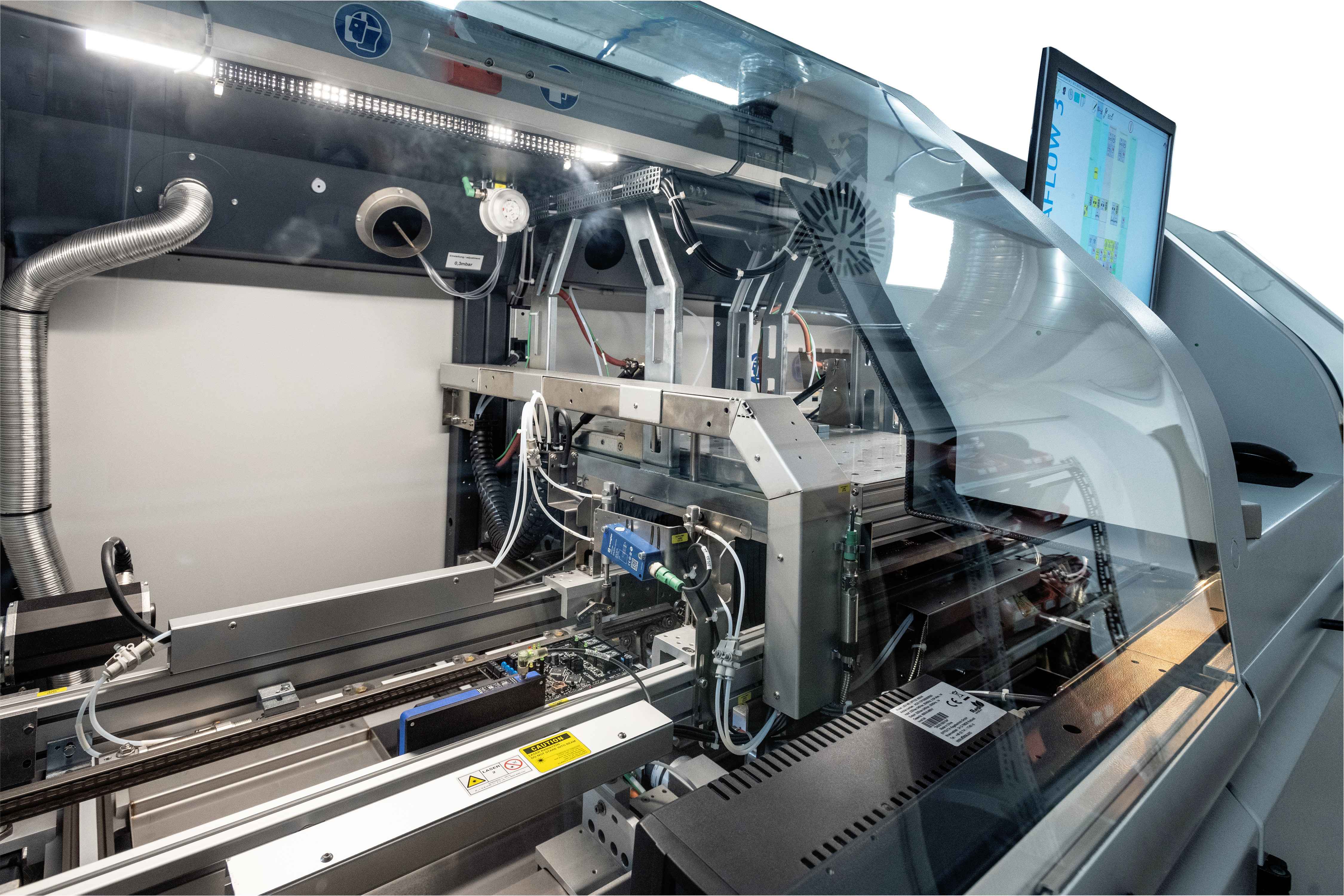

Selective Soldering

The Ersa Versaflow 3/35 Inline selective soldering machine is capable of soldering bore-mounted parts in high volume with controlled parameters and consistent quality thanks to its freely movable soldering module in the X-Y-Z direction. After loading the prepared PCB panels, the nozzle applies the flux (solder) according to the program, and after preheating on both sides, the soldering of the parts starts. The quality of the soldering can be continuously monitored using a high-resolution camera, so that intervention can be carried out more quickly in the event of failure.

X-ray Inspection

X-ray inspection is also available at Albacomp, a non-destructive inspection method that can be used primarily to inspect invisible solder joints or to look for solder air leaks. The Nikon XT V 130 C we use is equipped with an open-tube microfocus X-ray source that can produce real-time 2D images, but 3D construction is also possible. It is a configurable system according to user needs, with a rotating tray (true 72° tilt angle allows oblique viewing), automatic inspection software and a large tray size of 520x520mm.

We are manufacturing an increasing number of products containing components (BGA, LGA, QFN) with bottom leg outlets, the soldering of which cannot be checked by conventional means such as AOI. We are able to test all types of SMD components we insert and their solder joints, but typically we test the first finished product and then sample. Typically, it can detect inclusions, solder excess or shortage, mechanical damage, but it is also possible to inspect finished or semi-finished products, aluminium castings. The XT V 130C is a highly flexible and cost-effective electronics and semiconductor inspection system. The X-ray equipment includes a 130 kV / 10 watt Nikon Metrology source, a world-renowned open tube design with integrated generator and high-resolution imaging chain. More information: Nikon XTV 130

Electronics Cleaning

IThe InJet 888 is a 100% sealed washing, rinsing and drying system for the removal of soldering residues (Flux). All functions including washing, rinsing and drying are fully automated in one large chamber. It can be used with panels of different sizes and accessories (up to 850x800x600mm) with excellent results.

Why we love it:

- Solid, durable metal housing

- Simple, fast handling

- A wide range of useful accessories

- Various levels of user profiles

Automated Optical Inspection

Kohyoung Zenith Alpha AOI

The Zenith Alpha is a True 3D AOI solution powered by artificial intelligence and machine learning, combining the best optomechatronics and vision technologies to deliver outstanding performance without sacrificing accuracy.

- Enhanced 3D Measurement using Proprietary AI Technology.

- High Accuracy and Speed for Demanding Production Line (components up to 25mm through)

- Whole-board Foreign Material Inspection (WFMI) (combines 2D and 3D technologies to identify Foreign Object across the board).

- AI-Powered Auto Programming (KAP) (The innovative geometry-based Koh Young Auto Programming (KAP) software solution reduces the programming process to minimizes time to production and reduces costs.)

- KSMART Solutions: True 3D Measurement-based Process Control System

- Zero-defect through AI-Powered Koh Young Process Optimizer (KPO) Mounter (Using AI-based analysis, KPO Mounter provides users with actionable insights.)

Automated Conformal Coating

The best solution for protecting electrical circuits is to apply a lacquer coating to protect them against dust, moisture, chemicals and extreme temperatures. In addition, coating can also provide a solution against mechanical impact and vibration. This process can be carried out using a variety of tools, spraying, spray painting, etc., but the increasing complexity of products and growing demands have also made it necessary to automate this process. With the Nordson ASYMTEK lacquerer, we can provide the highest quality and productivity where accuracy and repeatability are important!