Efficient soldering with uniform heat transfer!

For medium volume production, where inline reflow solutions are not required, vapour phase technology is the right choice. In addition to production, the BGA is also suitable for reflow and adhesive curing tasks. The advantage of the vapour phase technology is that no time-consuming thermal profiling is required, any PCB can be soldered at high quality with low voids. The design of the machine allows soldering of the most complex boards up to 500x500x60mm (2kg) while ensuring optimum quality.

Other benefits include:

heat transfer is done by a liquid, so it is more effective

the heat is more efficient

reliable repeatability for all types of soldering

for lead-free soldering or even for adhesive curing

extremely low fouling

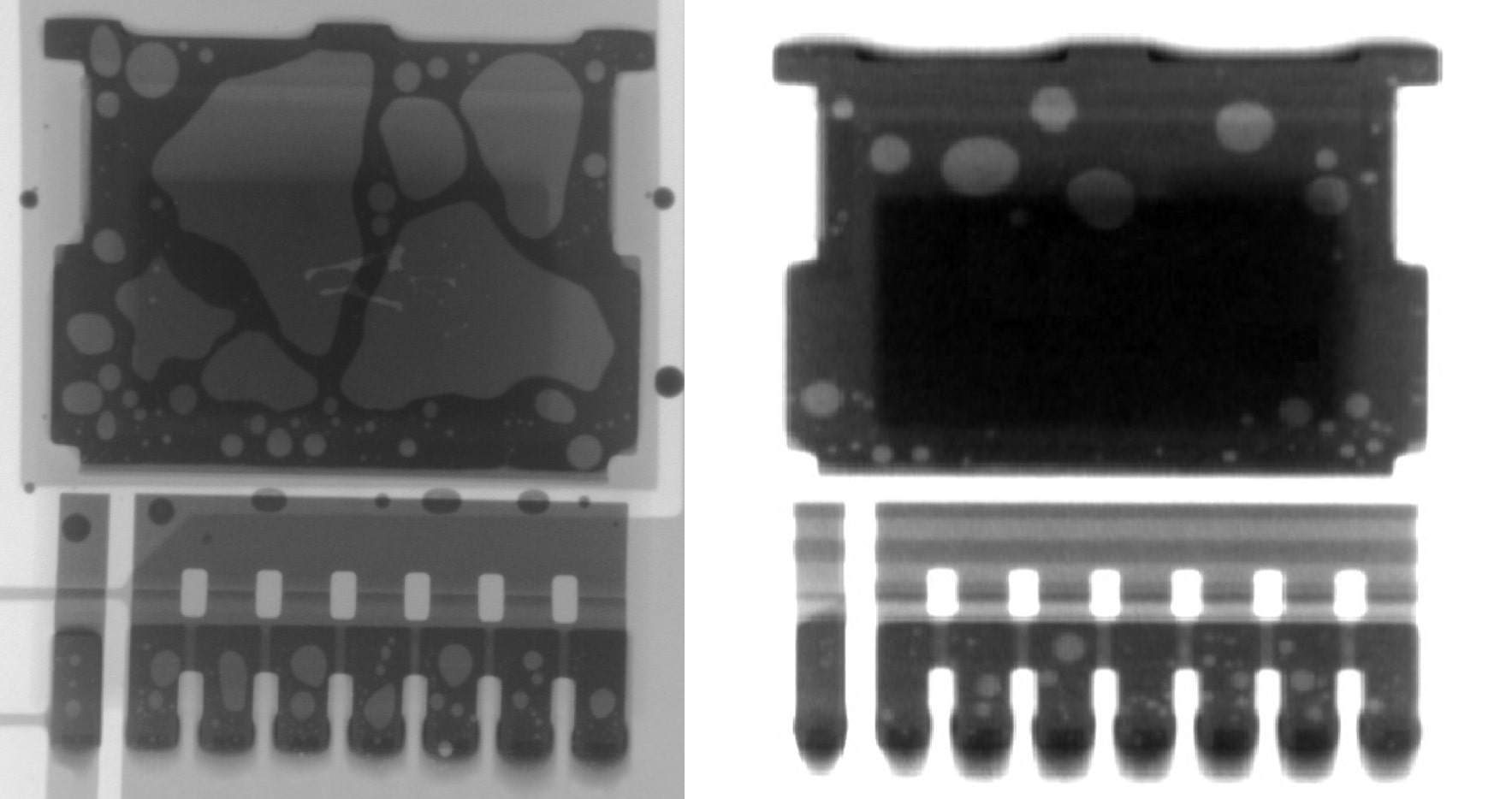

The picture below shows the formation of inclusions, there can be a significant difference between soldering processes. The product on the left was made in a conventional reflow oven, on the right by vapour phase soldering.

For more information, please visit the technology page, and if you have any further questions, please contact our Colleagues.