The development of SMD technology has significantly reduced the use of conventional components, but their use is still unavoidable in many applications. Typical passive components are connectors, switches and capacitors, which cannot be replaced by other components in electronics manufacturing.

Today, mixed assembly is also common, where high capacitance capacitors, transistors, inductors, transformers, mechanical components, switches and connectors are placed alongside SMD components.

The parts are prepared using special machines and tools to ensure smooth foot leads. With our EBSO and ITECO machines, we can undertake the bending and cutting to size of strapped, axial components, and with our special and custom-developed preparation tools, we can also meet specific requirements.

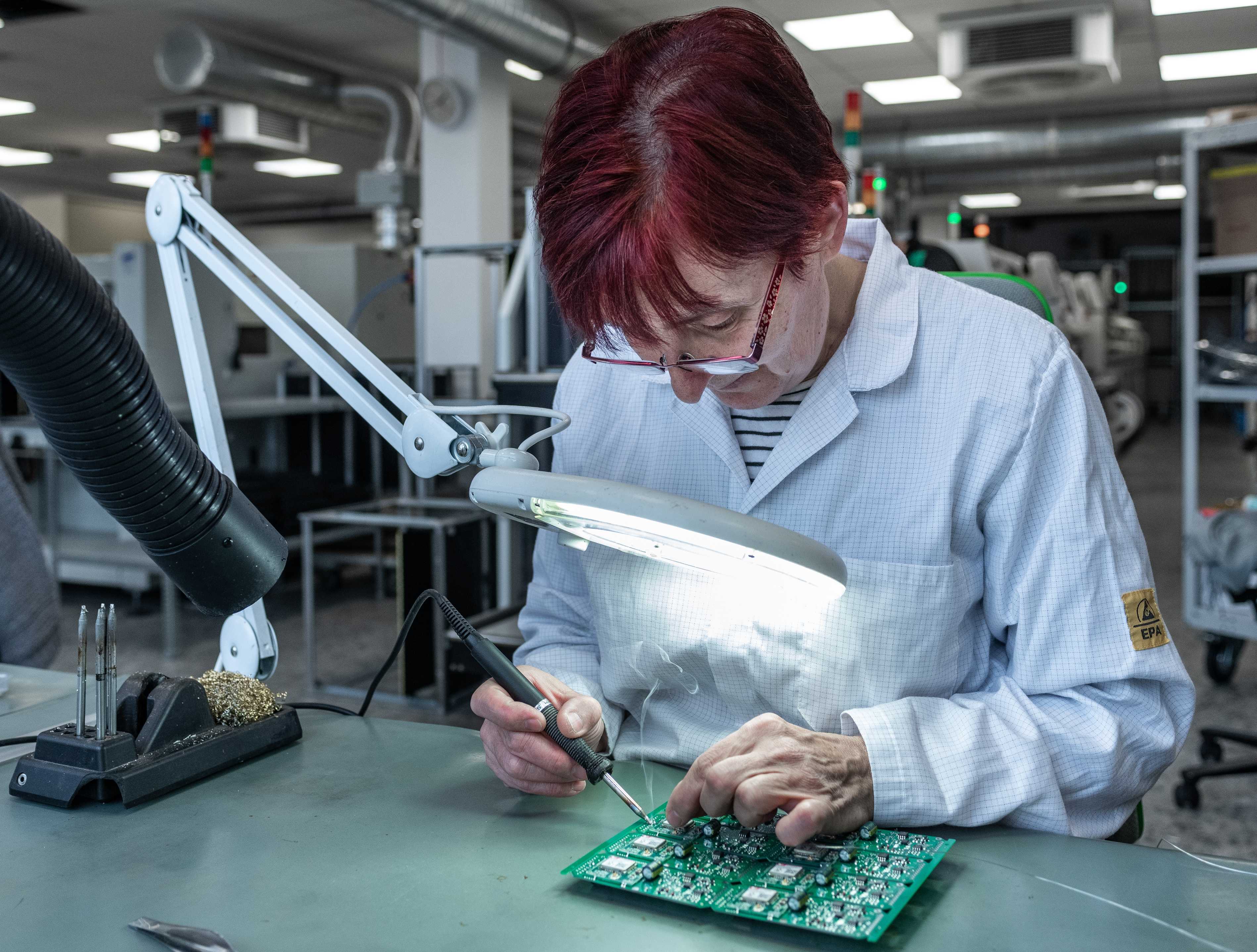

Traditional parts are fitted by staff with decades of experience, in an ESD protected environment, using state-of-the-art ERSA and JBC workstations.

For larger series, where soldering quality and repeatability are important, or where component legs are difficult to access and reheat, we use selective soldering stations. Thanks to this advanced technology, we can achieve a simple, repeatable and cost-effective production process.